Touchscreen Controller

Intuitive interface for greater control of your process

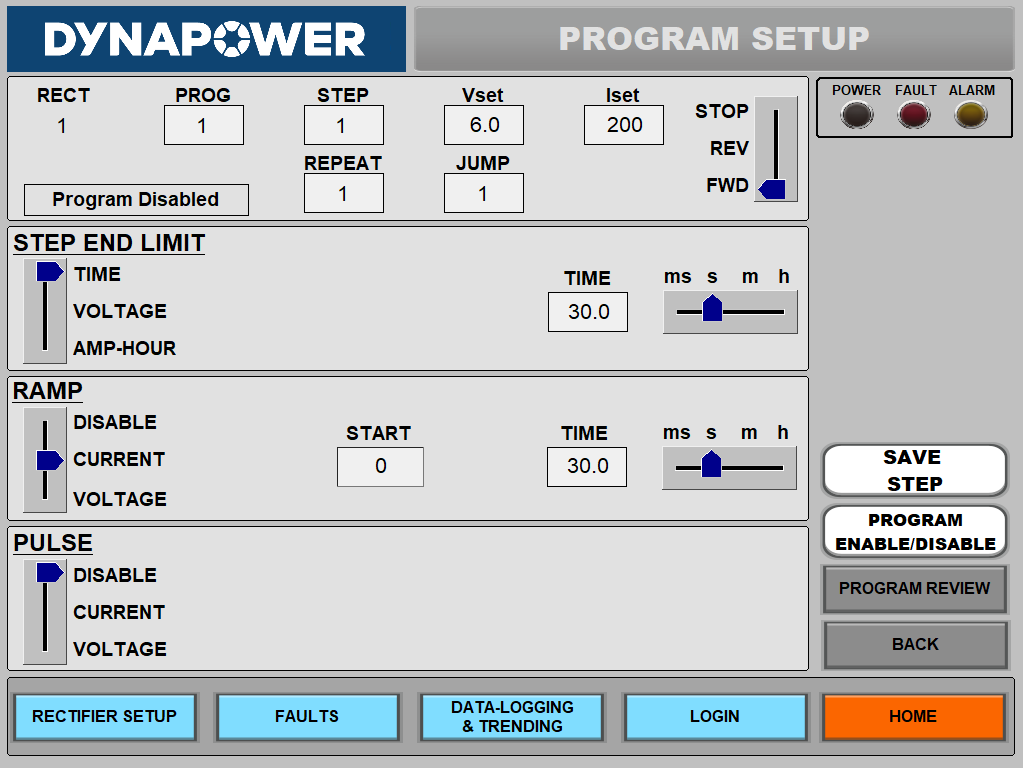

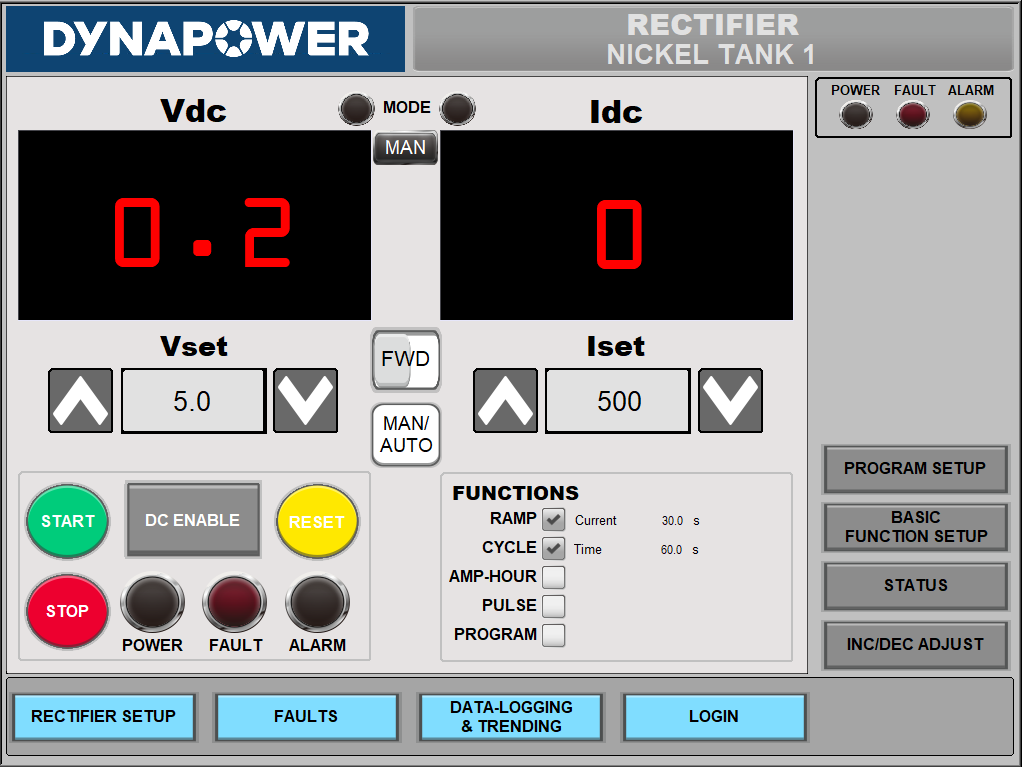

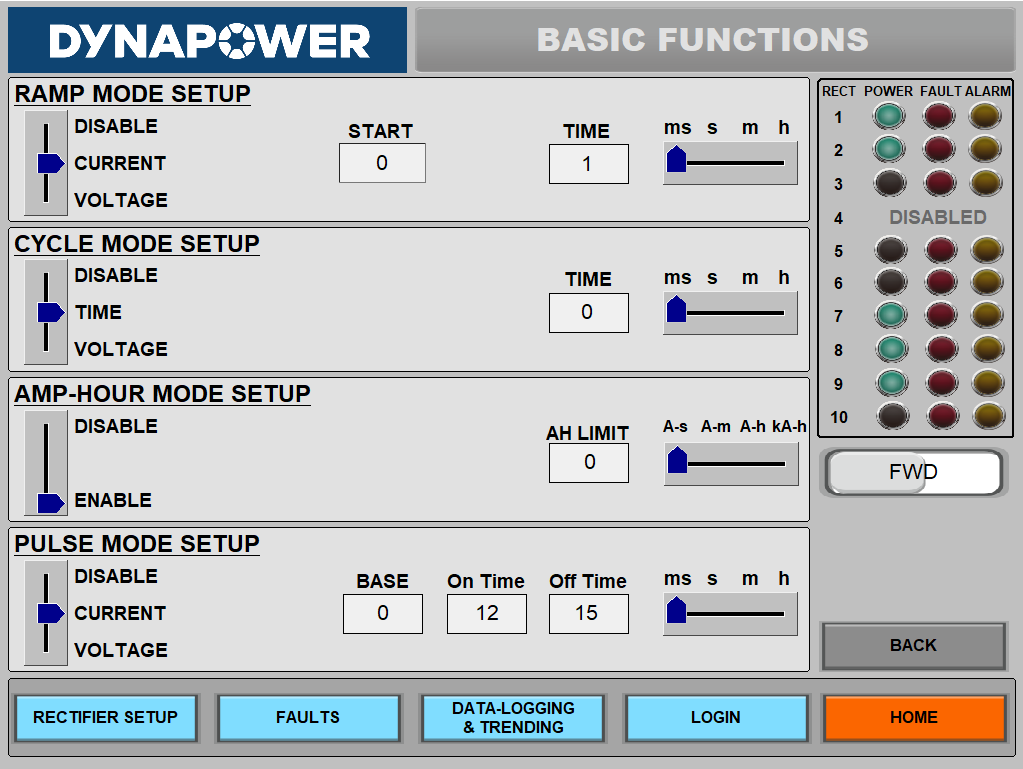

Our advanced Touchscreen Controller uses a graphic display with menus that are easy to navigate, allowing you to quickly create recipes and view status indications, controller setup, and special operating modes.

Easily integrated with SCR and switchmode rectifiers, this controller offers ultimate unit control that has never been faster or easier. With its time-saving profile mode, it can create, store, and use multi-step custom recipes that include ramp, dwell, pulse, amp-hour, and cycle functions. Precise adjustments can be made to voltage and current set-points, ramping time and rate, dwell time, pulse duration, cycle time, and amp-hour set-points, all with just a few quick taps.

The Touchscreen Controller comes built into a standard remote console, allowing for flexible controller placement. Custom control placement options are also available on request. It can also be retrofitted to existing Dynapower power supplies or SCR units supplied from other manufacturers.

Features

- Graphic display for viewing unit output, set-point reference levels, status indication, setup, and special operating modes

- Voltage and Current set-point adjust

- Ramp rate set-point adjust for both Voltage and Current modes

- Amp-hour set-point adjust

- Amp-hour totalizer with 8 digit resolution

- Cycle timer set-point adjust

- Pulse set-point adjust for both Voltage and Current modes

- Recipe storage:

- Store up to 16 multi-step programs

- Each program contains up to 8 steps that include ramp, dwell, pulse, amp-hour, and cycle functions

- Selectable time-base of milliseconds, seconds, minutes, or hours for all timers

- Concurrently running operating modes to allow for complex waveforms

- Steps can be configured for either ramping or constant set-points

- Programs and set-points automatically restore upon power-up

- Process alarms

- Fault indication

- In depth alarm and fault history reports

- Voltage and current trend information

- Polarity reversal function

- Remote interface via Ethernet TCP/IP, Profibus, or Modbus for easy multi-unit integration

Let’s power up together

Take the first step toward a higher level of performance and reliability. Call us at 1 (802) 860-7200 or click the link below to schedule an appointment today.